Top Notch Injection Moulding

Services In Australia

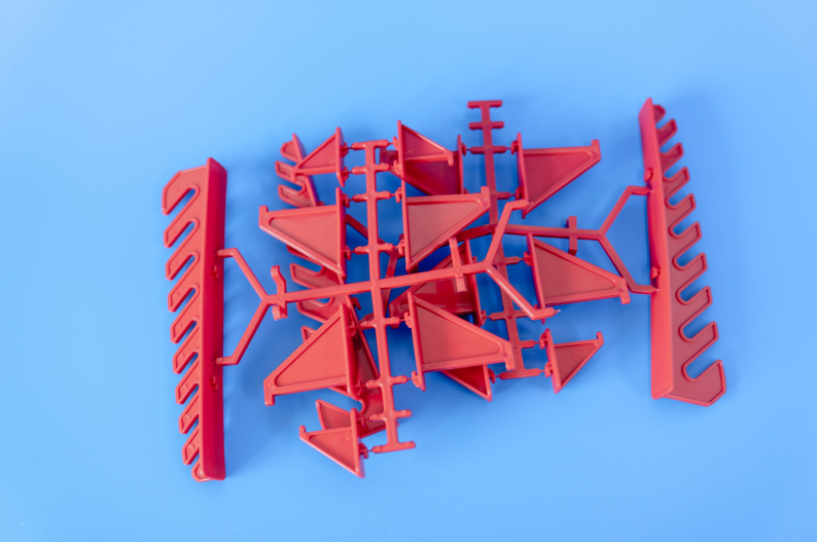

We are specialized in providing you the best plastic injection moulding printing to fulfill all your manufacturing needs. In our injection moulding process we make use of a variety of plastic materials such as ABS, POM, Styrene, PVC, nylon, and other resins to manufacture parts of ships or other vehicles specially used in marine or automotive industries. These services make use of superior quality chromium steel moulds to maintain toughness and resistance

Injection moulding is processed with various other types such as Cube, micro, metal, and silicone injection moulding, ensuring mass production.

Trusted partnerships, unrivaled results CAD Deziner’s track record

How Does Our 3d Printing Company Work?

Our company works by providing our customers with 3D printing services tailored to their specific needs. We utilize the latest technologies, 3D printers, and inks to produce high-quality products. Our experienced technicians and 3D printers are capable of producing parts with complex shapes and designs quickly and accurately.

Upload CAD file

Securely upload your part design to our online quote builder.

Confirm specs

Configure your part specifications and select a lead time that suits your schedule.

Receive instant quote

Upload your CAD to our online quoting platform

Manufacturing

We select the best manufacturer for your order, and production begins immediately.

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Why Choose Us For Injection Moulding Services

For years, we have provided exceptional manufacturing services , including injection moulding Brisbane. Today, we proudly claim that we are the best in the business. We design great and unique models for automobile, construction, medical, dental, aviation, fashion and many more industries. The plastic models that we make have enough quality to be used on an industrial level. In short, we provide the best Plastic injection moulding service in Sydney, Melbourne, Perth, and Brisbane.

Another reason that customers are attracted to us is the price. We provide one of the most affordable prices for injection moulding service. It is because we prioritize customer satisfaction more than anything.

Also, know that employees at CADEZINERS Innovative Solutions are skilled enough to design highly complex plastic models.

Here are some of the benefits to choose our plastic injection moulding Perth:

- Availability of advanced moulding technology.

- Ability to create highly complex geometrical models.

- Availability of tools.

- Dependability in parts conveyance.

- Availability of unlimited reproduction.

We at CADEZINERS Innovative Solutions provide exceptional injection moulding Sydney along with plastic moulding services. Our injection moulding services include plastic injection moulding, metal injection moulding, rubber moulding (rubber compression moulding, rubber injection moulding, and rubber transfer moulding), foam injection moulding, and micro injection moulding. CADEZINERS Innovative Solutions uses the latest technology to provide the most durable and high-quality injection moulded products.

Injection moulding has various applications. The plastic housing that we make using injection moulding can be used in many products, including automotive dashboards, power tools, household appliances, and consumer electronics. Injection moulding is also used for mechanical parts, medical devices, and more. In short, injection moulding is a great method for creating any plastic product that you can think of.

Injection moulding can help you create products in high volume. If you want to create a bulk of the same models with plastic, there is no better option than injection moulding.

We at CADEZINERS Innovative Solutions provide injection moulding services with a wide range of materials. We provide injection moulding in Australia using materials like Acetal, Nylon, ABS, PEI, PET, Polyethylene, Styrene, Polypropylene, TPE, etc. Selecting the suitable material for your design can be challenging, but don’t worry. Our professional and skilled employees are here to help. Our employees will help you to select the suitable material for your product and design. We don’t just provide injection moulding services, but we also provide the finishing touch to look as aesthetically as possible. We use a variety of materials and methods for finishing, including electroplating, water transfer, perforated finish, glossy/matte finish, painting, and more.

Accuracy is one of the concerns when using injection moulded products. The accuracy depends upon the material, tooling, product’s geometry, and surface finishing. For most thermoplastic, the average tolerance is ±0.2 to 0.5 mm. In some specialized cases, the tolerance can be as low as ∓5μm. In mass products, we can quickly achieve 0.0500 to 0.1000μm.

Plastic injection moulding is the best way to create affordable designs quickly at a very low cost. The products that we design using plastic injection moulding are high in quality and qualify the industrial standards. Our employees at CADEZINERS Innovative Solutions are skillful in designing 3D plastic models using laser-based rapid prototyping techniques.

The main advantage of plastic injection moulding is that you can use this technique to test the design. Once the design is successful, you can go for mass production. We have vast experience in plastic injection moulding. Our workspace has the ability to create quick prototype models quickly. You get all you need at 3d Prinitngs Innovative Solutions.

metal injection moulding

Metal moulding is the upgraded and advanced version of plastic injection moulding. Engineers use metal injection moulding to fabricate solid metals. Feedstock (a raw material) is used as the metal and polymer powder for metal injection moulding.

For metal injection moulding, the metal powder is melted and put into the moulding machine. The machine shapes the molten metal, and then it is left to cool down. To remove unnecessary polymers, a heating process is used. Once the polymer is removed, the product becomes highly dense and durable.

For Metal Injection Moulding, we commonly use the following metals:

- Iron

- Cobalt alloys

- Tungsten Alloys

- Copper Alloys

- Stainless steel

rubber moulding

Rubber moulding is the process of creating products made of rubber or elastomer. In rubber moulding, the rubber is pressed hard on a metal cavity by a moulding machine. The rubber is also heated to activate specific chemical reactions. To achieve the desired quality, multiple techniques are used. The most common rubber moulding techniques are transfer moulding, injection moulding, and compression moulding.

In this method, professionals use a fixed rubber compound on a mould cavity. The pressure is applied to compress the rubber into the cavity shape. In compression moulding, the pressure remains constant, but more heat can be added to cure the product.

In injection moulding, the rubber is heated until it becomes liquid. After that, it is injected into the mould.

The rubber is first placed on a pot and then pushed to the cavity to get the desired shape. When the shape is generated on rubber, the mould is split, and the rubber is released.

We use a wide range of materials for rubber moulding, including:

- Nitrile

- Hydrogenated Nitrile

- Ethylene Propylene Diene Monomer

- Silicone

- Natural Rubber

Foam injection moulding is the best way to create lightweight yet durable and sturdy models. When you want to make large objects with accessibility features and thick walls, foam injection moulding is the best technique to get them. The foam provides a quick turnaround when you work with thicker parts.

Another advantage of foam injection moulding is that the process is quite affordable. This means you get a thicker, better, and more durable lightweight object at a low price. Some other benefits of using this technique are:

- Low cost

- Capability to design complex objects

- Improvement in dimensional stability

- Cost-effective

- Highly efficient

- Less material usage

Micro Injection Moulding

Micro injection moulding is the most advanced technology to producea tiny complex object from plastic. This updated technology can produce objects as light as 0.1gm. The tolerance level of micro injection moulding ranges from 10 to 100 microns.

Following are some of the industrial sectors that use micro injection moulding technology:

- Automotive

- Healthcare

- Electronics

- Pharmaceutical

- Fashion

Following are some of the materials that we use in micro injection moulding:

- Polypropylene

- Polyethylene

- Nylon

- Polysulfone

- Acrylics

- Polybutylene terephthalate