Custom Fused Deposition Modelling (FDM)

Services Across Australia

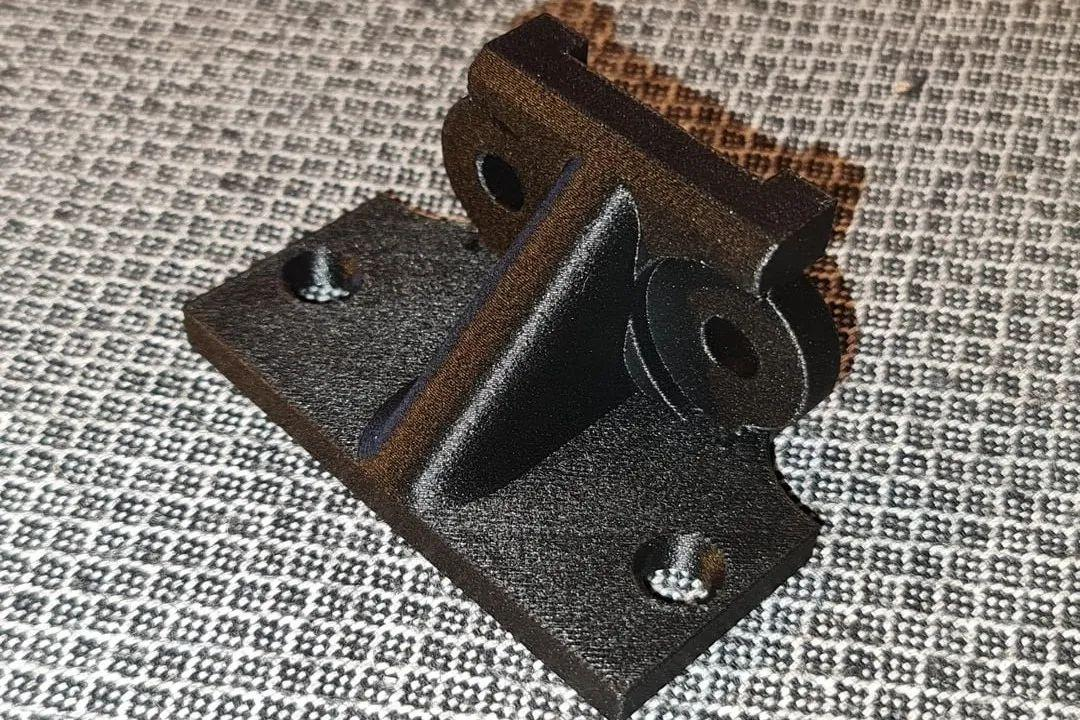

FDM stands for Fused Deposition Modeling. It is a technology that allows different industries to create concept designs for their products. It is a great prototyping technology that has been used by different industries, including healthcare, automobile, construction, etc. The name FDM itself tells the story behind this technology. The plastic is melted in liquid form then it is deposited by the system in both single and multi-layers. Layers are fused together to form the 3D model.

Trusted Partnerships with Unrivaled Track Record

How Does Our Company Work?

Our company works by providing our customers with services tailored to their specific needs. We utilize the latest technologies, 3D printers, and inks to produce high-quality products. Our experienced technicians and 3D printers are capable of producing parts with complex shapes and designs quickly and accurately.

Upload CAD file

Securely upload your part design to our online quote builder.

Confirm specs

Configure your part specifications and select a lead time that suits your schedule.

Receive instant quote

Upload your CAD to our online quoting platform

Manufacturing

We select the best manufacturer for your order, and production begins immediately.

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

How does FDM 3d Printing work?

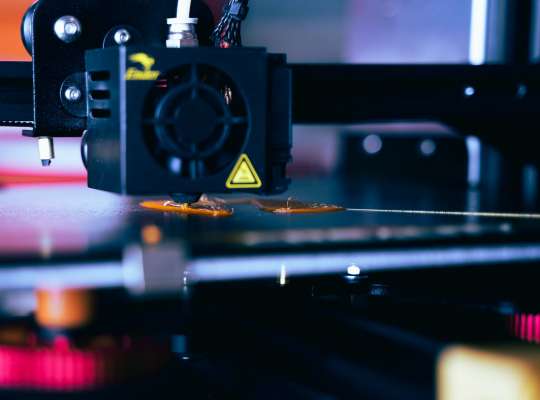

- Computer Aided Design Files are required in .STL format.

- Material is fed into the extruding. The thermoplastic material comes in the form of a spool.

- The cold end of the printer pulls the material from the spool and pushes it into the hot end, which consists of an extrusion head and a nozzle.

- They are further connected by a computer which controls the x, y, and z axis during the printing of the part.

- The material is collected layer by layer, and it cools down and solidifies.

- When one layer is deposited by the extrusion head, it is pushed down to the build platform, and a new layer is formed. This process is repeated until the part is completed.

We have been continuously leading the market in the production of highly accurate and durable parts for the past eight years. Our team of expert designers provides the best solutions for printing complex parts. We offer cheap and efficient 3D Printing services in Melbourne, Perth, Sydney, and Brisbane. In short, our services are the best FDM printing services in Australia.

Some other benefits include:

- Cost-effectiveness

- Lesser lead times

- Used for a wide range of prototyping products

Benefits of FDM 3d Printing

FDM produces parts with great precision and accuracy. The parts have a strong build and are durable, which is the primary reason why FDM 3D printing technology is widely used. Some other benefits include:

COST EFFECTIVENESS– Fused Deposition Modeling is widely used for prototyping because it is highly cost effective. You don’t need to pay much yet to get a lot. The price that we charge for FDM 3D printing is extremely reasonable. In fact, we provide one of the cheapest FDM 3D printing services in terms of price.

Lesser Lead Times- If you are in a hurry and want your model to be printed in no time, then there is no better option than Fused Deposition Modeling. You can contact us, and we will print anything for you within a given time.

Prototyping Products- FDM 3D printing is the best way to test your concept by printing their prototypes. FDM requires less cost and less time, plus their material is also cheap. Hence, you can print multiple prototypes and compare them to find the right one. In this way, you will be able to improve your overall design and concept.

Availability of material- FDM 3D printing technology uses polymers for printing prototypes. At our workspace, we have a wide range of materials suitable for your prototype. We more than 18 different material options using FDM Process.

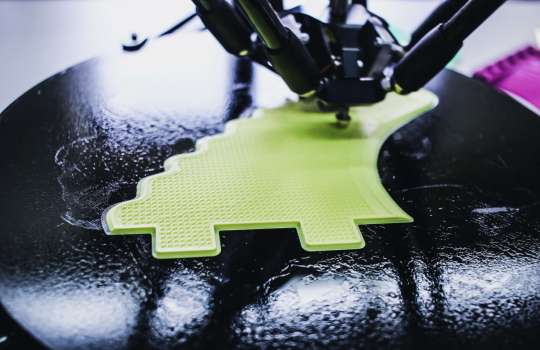

Many industrial professionals used FDM 3D printers to test their models. Medical professionals and engineers print prototypes of their concept models before going for mass products.

This allows industries to test early concepts. You can FDM print multiple designs and concepts to check which fits the most. In this way, FDM printing saves a lot of money and time.

People also use FDM printers for medium fidelity prototyping. Medium fidelity prototypes are 3D printed objects that look almost like the actual parts. The resolution used for Medium Fidelity Prototyping is 0.1 mm layers. If you want to feel and check the performance of your prototype, then this option is ideal for you.

We can 3D print using FDM technology almost anything. It doesn’t matter how big your model is, bring your concept to us, and we will print it for you. Also, the complexity of the object doesn’t matter. Our employees are expert enough to bring any concept into reality. On average, our printers can print upto 900 mm x 600 mm x 900 mm.

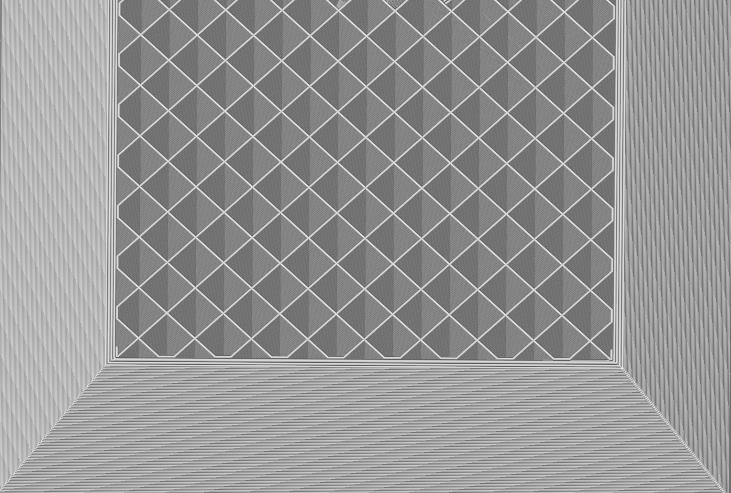

FDM Infill Options

Solid

Light

Ultralight

Fused Deposition Modeling (FDM) OR Fused Filament Fabrication:

FDM 3D Printing is the most widely used additive manufacturing process which involves the fusion of layers of materials together to create a part. FDM 3D printing employs thermoplastic material as a filament to produce the best quality and strong parts with the help of a CAD model. The material is fed into the heated 3D printer end, thereby melting it and creating a structure by depositing the layers of the material. FDM 3D Printing is the most used process for fabricating industry grade parts. This technique is fairly simple and widely accepted.

The Biggest advantage of FDM printing is scalability and material flexibility. FDM can provide high finish standards after various post-processing methods such as polishing, painting, and cold welding. Our printing services provide shorter lead times and economic costs.

3D printing has proved to be a revolutionary tool for dentistry. Experts use all the required materials and tools to produce multitude of things. These include orthodontic models, precise crown and bridge models, castable or pressable restorations, retainers, and aligners. Moreover, they are now also using it for the production of biocompatible dental objects like dentures and splints.

Construction Industry: This happens to be one of the industries, especially in Australia, that is making great usage of this technology. The process is leveraged to print the models of entire buildings; these 3D models of the whole structure provide great help to builders to make the desired building. Along with this, the tools also help in the creation of construction machinery. This method in construction has allowed for faster and more accurate construction of bespoke projects. Moreover, it has also significantly lowered the labour costs and cut down on wastage.

FDM 3D Printing Materials – Specifications Overview

| Material Name | Surface Texture | Minimum Feature Size | Minimum Wall Thickness | Maximum Build Volume (mm) |

| PLA(FDM) | Slightly rough | 1.0mm | 1.0mm | 900x600x900mm |

| ABS-M30i | Slightly rough | 1.0mm | 1.0mm | 900x600x900mm |

| ASA | Slightly rough | 1.0mm | 1.0mm | 900x600x900mm |

| PC-ISO | Slightly rough | 1.0mm | 1.0mm | 900x600x900mm |

| PC-ABS | Slightly rough | 1.0mm | 1.0mm | 900x600x900mm |

| NYLON 6 | Slightly rough | 1.0mm | 1.0mm | 900x600x900mm |

| NYLON 12 | Slightly rough | 1.0mm | 1.0mm | 900x600x900mm |

| NYLON 12CF | Slightly rough | 1.0mm | 1.0mm | 900x600x900mm |

| Vero pure white | Ultra smooth surface | 0.7mm | 1mm | 490x390x200mm |

| Vero Black Plus | Ultra smooth surface | 0.7mm | 1mm | 490x390x200mm |

| MED-610 | Ultra smooth surface | 0.7mm | 1mm | 490x390x200mm |

| ASA(UV resistant) | Slightly Rough | 1.0mm | 1.0mm | 914mm X 609mm X 914 mm |

| ULTEM 9085 | Slightly Rough | 1.0mm | 1.0mm | 914mm X 609mm X 914 mm |

| ULTEM 1010(FDM) | Slightly Rough | 1.0mm | 1.0mm | 914mm X 609mm X 914 mm |