Polyjet 3d Printing Service In Australia

In this Polyjet 3d printing technology, layers of curable liquid photopolymer are jet onto a build tray. A 3d CAD model is used to determine the placement of photopolymers and the removable support material.

About Polyjet printing

Polyjet is a 3D Printing technology that is used for producing smooth and highly accurate parts. In this 3d printing technology, layers of curable liquid photo polymer are jet onto a build tray. A 3d CAD model is used to determine the placement of photo polymers and the removable support material. Fine layers are accumulated on the build tray and complex and intricate designs are created. After the completion of the photo polymerization process, the batch is kept under pressurized water jet in order to remove the support materials. Polyjet provides multiple print heads and create different variety of colors and properties.Due to multiple print heads, multiple materials can be printed at the same time. The end result of the process yields a finely detailed part with smooth surface and high precision.

The Process :

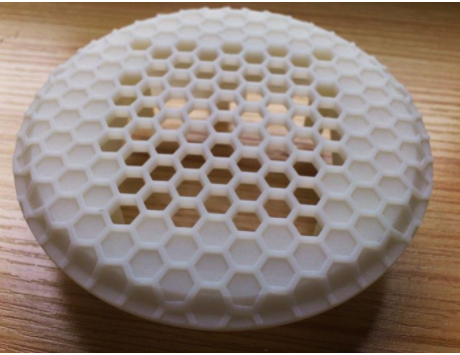

This process is beneficial for creating smooth and accurate prototypes. Complex shapes with intricate and delicate details can be easily created with a microscopic resolution and accuracy of 0.014mm. A variety of materials and colors are available for printing any object. The parts printed are realistic with smooth surface and are finely detailed. Polyjet products have vast range of materials from hard plastic to soft material like rubber.

Benefits Of PolyJet/MJP:

- PolyJet has the exclusive capacity to produce parts and components in a single construct that are made of various elements, colour schemes, thickness, and physical or mechanical attributes.

- PolyJet can create highly complex mechanical parts, allowing you to get high prototypes in a smaller duration of time.

Benefits Of Polyjet/MJP With Us

Our Polyjet/MJP solutions allow you to create 3D printed models and components in various materials. In addition, the prototypes made from this technique are used in marine, automotive, mining, and engineering testing sectors.

PolyJet is a cutting-edge 3D printing approach that combines smooth, precise components, prototypes, and manufacturing. It can create thin walls and complex geometries using the widest variety of items accessible with any technology, with microscopic surface precision and precision down to 0.014 mm. PolyJet is a 3D printing technology that generates parts by spraying thousands of photopolymer granules onto a constructed framework and curing them with ultraviolet light. It is the fastest emerging and most precise 3d printing technique accessible to all industries.

PolyJet vs MJP

The construction materials, their components, and post-processing approaches vary between (MJP) and (PJP). Both are related to Material Jetting Technology, in which the build substances (photo-sensitive resins) are processed and treated under UV light using an inkjet printing technique. The variations can be seen in the types of materials used and the design, surface finish, precision, and implementations.

With the help of MJP, you can only print a single type of material; multiple types of materials cannot be printed in a single build. MJP is used to create high-quality components, designs, and moulds for a wide variety of applications. On the other hand, PJP can print multi-material prototypes in a single build. PJP is used in injection moulding, prostheses, dental laboratories, architectural and other applications.

The support materials in MJP are distinct, meltable, and soluble, making post-processing a breeze. On the other hand, The support material in PJP is a gel-like product that is quickly wiped away.

Convection baking, infrared wash, oil-based bath, washing with warm soap water, and other post-processing tasks are performed at MJP. In PJP, however, cosmetic presentation is achieved by post-processing tasks such as sanding, water jetting, and powder coating.

Benefits of Polyjet printing

- Better Quality Models – The process uses photopolymers and Ultraviolet energy to treat plastics. PolyJet is identical to the stereolithography (SLA) process of 3D printing. Whenever it comes to complexity and precision, it is the best way. PolyJet is the industry’s fastest process and can concentrate material in layers as thin as 16 microns, resulting in models with highly complicated geometries and extraordinary quality and sharpness for high-precision moulds, jigs, fixtures, and other manufacturing equipment.

- Easier post-processing – PolyJet’s support material is readily removed by hand, which is a significant advantage over SLA, where such substance must be dusted away during post-processing. Many 3D printing techniques allow support material during manufacturing to ensure precision, anchor sections to the build platform and help construct fragile elongated features.

- User-friendly software – CAD software, which recognizes and communicates CAD files natively and simplifies the preparation, planning, tracking, and reporting of print jobs, is assisted by the entire range of our 3D printers. It permits you to get its prints right from your preferred, advanced CAD formats, preserving hours that would otherwise spend translating and repairing STL files.

Industries where Polyjet can be used

Polyjet Printing Methods

| Material Name | Quality | Min Details | Minimum Wall Thickness | Maximum Size |

| Sandstone | Smooth finish | 0.4mm | 2mm | 380x250x200 |

| Multicolour polyjet | Ultra smooth finish | 0.2mm | 1mm | 250x250x200 |

| UV Cured Acrylic (MJM) | Very smooth Finish | 0.1mm | 0.8mm | 284x184x203mm |

| Transparent Acrylic (MJM) | Very smooth Finish | 0.1mm | 0.7mm | 284x184x203mm |

| Castable Wax (MJM) | Very smooth Finish | 0.1mm | 0.6mm | 75x75x50mm |

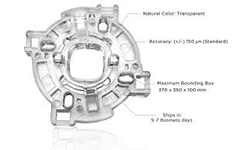

| VeroClear(Transperent)(PolyJet) | Very smooth Finish | 0.7mm | 0.1mm | 490 X 390 X 200 mm |

| PP Grade(PolyJet) | Very smooth surface Finish | 0.7mm | 0.1mm | 490 X 390 X 200 mm |

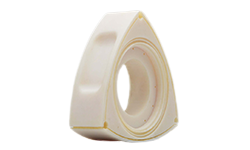

| Agilus30(Flexible and Tear Resistant)Polyjet | Very smooth surface Finish | 0.7mm | 1.0mm | 490 X 390 X 200 mm |

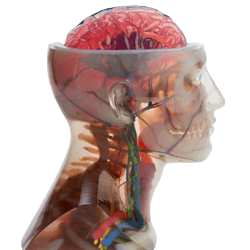

| MED610 (Medical grade)(PolyJet) | Very smooth Finish | 0.7mm | 1.0mm | 490 X 390 X 200mm |