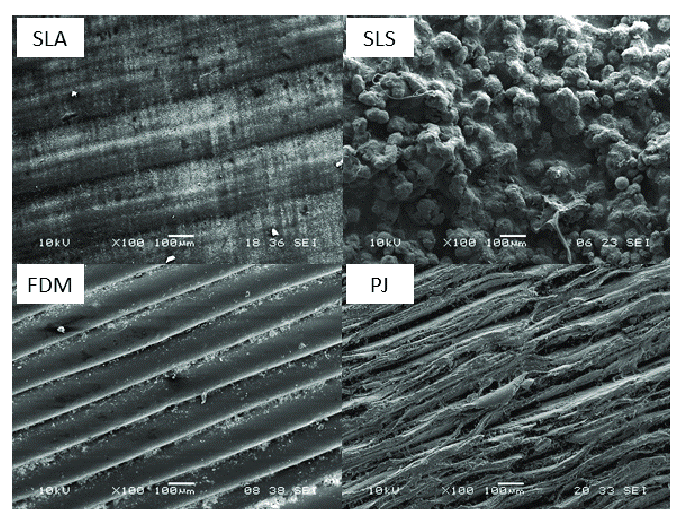

SLA vs SLS – What is the difference?

Additive manufacturing (AM), also called additive layer manufacturing (ALM), is the most common printing technology used in different industries. It is a computer-aided process that produces three-dimensional objects by depositing materials, usually in layers.

You can find many technologies and variants, but the SLA and SLS technologies are the most widespread within the industry.

We will let you know the difference between these technologies in this blog. Keep reading to get a good explanation!

Overview of SLA and SLS Technologies

Here’s an overview of both 3D technologies with their advantages, followed by the key differences between them.

Selective Photopolymerization of Resins (SLA)

SLA refers to stereolithography technology. In this process, a liquid photo-polymer is converted into a solid plastic layer using a laser. Each layer is different, and a 3D model is created on a perforated plate.

This technology appeared in the 80s, and today, SLA allows printing on a wide range of materials with good mechanical properties. Many companies use it to make detailed parts through vacuum casting polyurethane and silicone moulds.

Advantages of SLA

- Relatively fast turnaround times

- Suitable for models complex in nature

- Simple scalability

- No human factor

- No wasted materials

- Support biomedical moulding

Selective Laser Sintering (SLS)

On the other hand, SLS technology was also commercially developed in the mid-1980s. Like SLA, SLS uses layered printing that solidifies the liquid. This technology uses a higher power laser that sinters plastic powder. The material used is Polyamide/Nylon, although Polyamide with fibreglass filler is also used.

Traditionally, parts manufactured with this 3D technology offer more excellent resistance than those produced in SLA.

Advantages of SLS

- High-resolution levels

- Fast and smooth production

- Fantastic mechanical properties

- Stiffness with high strength

- Wide selection of materials

The Difference Between SLA and SLS Technologies

Here is a practical comparison highlighting the fundamental differences between SLA and SLS technologies:

- The Processed Material: SLS uses solid materials, including polyamide powder, glass-filled nylon, alumide, and carbon fibre-filled nylon. In SLA technology, the materials (also called substitutions materials) include resin (liquid base) for additive manufacturing.

- Properties of the Printed Object: The SLS printed objects have resistance to high temperatures with greater impact resistance. The SLA does not resist high temperatures well, becoming deformed at above 60 degrees Celsius, and is less resistant to impacts.

Which Printing Technology is Better?

When assessing which of the two printing technologies is better, something that many ask us, the answer is: it depends on your aim and what kind of object you want. The needs of some are different from those of others.

Clearly, anyone needing a robust product will have to focus on SLS 3D printers. On the other hand, SLA 3D printers are suitable for those who just want to get a prototype quickly and don’t want to go through the hassle of hand-finishing objects.

Final Words

This printing technology encompasses different technologies within the broader term. As highlighted, the top two technologies currently used worldwide are SLS and SLA, dominating the market. Understanding the differences between these technologies will help you choose the one that best suits your printing needs.

Recent Posts

-

How the Entertainment Industry Uses 3D Printing for Faster Props, Costumes & Sets26 Feb 2026

How the Entertainment Industry Uses 3D Printing for Faster Props, Costumes & Sets26 Feb 2026 -

The Environmental Impact of 3D Printing: A Practical Path to Carbon Footprint Reduction26 Feb 2026

The Environmental Impact of 3D Printing: A Practical Path to Carbon Footprint Reduction26 Feb 2026 -

Why UV-Protected 3D Printed Parts Are Essential for Outdoor Use in Australia26 Feb 2026

Why UV-Protected 3D Printed Parts Are Essential for Outdoor Use in Australia26 Feb 2026 -

Why Aerospace Companies Are Adopting 3D Printing for Lightweight Components26 Feb 2026

Why Aerospace Companies Are Adopting 3D Printing for Lightweight Components26 Feb 2026 -

Top 3D Printing Trends Shaping Industries in 202627 Jan 2026

Top 3D Printing Trends Shaping Industries in 202627 Jan 2026