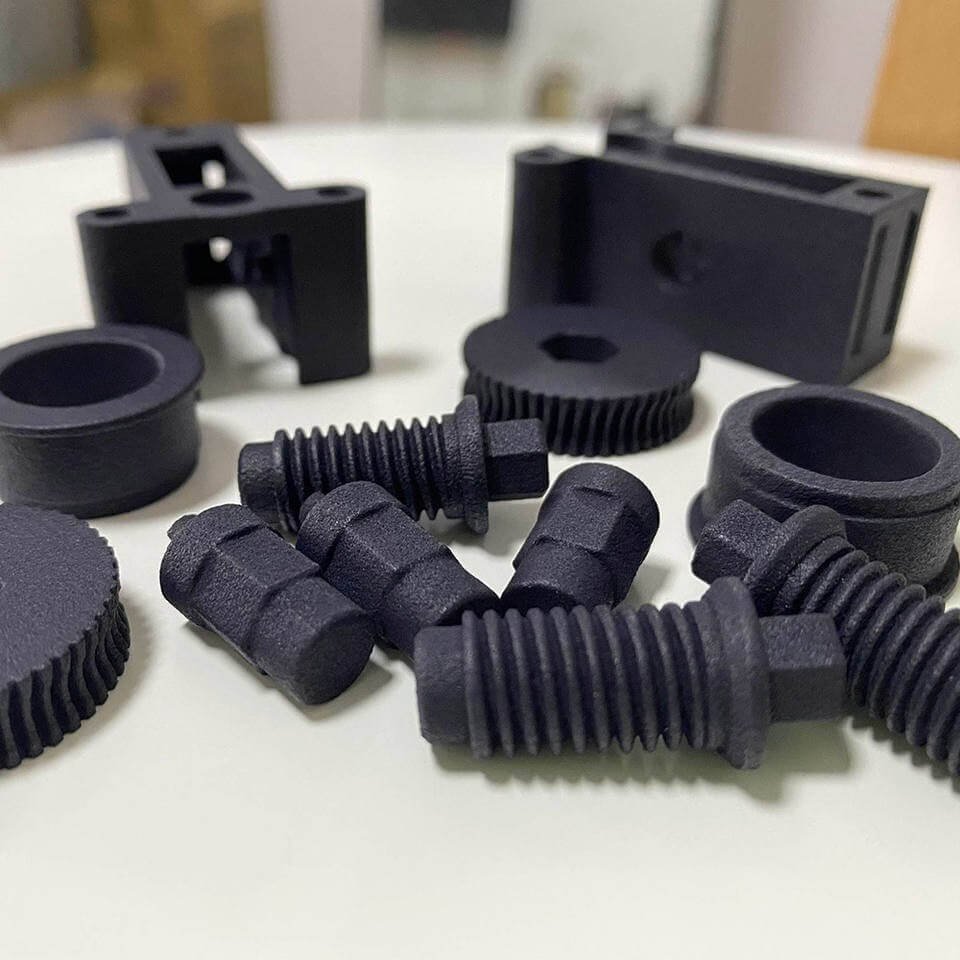

Get The Best Powder Bed Fusion Service In Australia

Powder Bed 3D printing is steadily emerging as an invaluable tool for the manufacturing industry. By using high-powered lasers to precisely manipulate metal powders, components can be created with complex shapes and detailed features not possible with traditional machining and fabrication methods. The versatility of Powder Bed Fusion 3D printing allows for near-complete design and performance customization, allowing for an unprecedented level of precision engineering. It can also allow for more efficient production processes due to its ability to create objects of intricate designs in a single operation that would require multiple operations with traditional techniques.

Trusted partnerships, unrivaled results CAD Deziner’s track record

Process of Powder Bed 3D Printing

- The process begins with preparing the build chamber, which is usually enclosed to maintain a controlled environment.

- A thin layer of metal powder is spread uniformly over the build platform.

- A high-powered laser beam is directed onto the powder bed, selectively melting the metal powder in specific areas to create the desired shape of the part. The laser’s intensity and the scanning speed can be precisely controlled to ensure the correct amount of melting occurs.

- After each layer is melted, the platform is lowered, and a new layer of powder is spread. The previous layer cools and solidifies as the process continues.

- The process repeats until the entire part is complete. The build chamber can be opened once the part is cooled down and removed from the platform.

- Once the part is removed from the platform, it requires post-processing to achieve the desired surface finish, mechanical properties, and dimensional accuracy. This may involve polishing, heat treatment, or other techniques.

- The final step involves quality control, where the part is inspected to ensure it meets the desired specifications. This may involve x-ray or CT scanning, dimensional inspection, or other techniques.

Benefits of Powder Bed Fusion

High Accuracy and Resolution

Powder bed 3d printer create objects with extremely high accuracy and resolution. This means that complex structures can be printed with great precision and detail, allowing engineers to make intricate objects that are not possible with other forms of manufacturing. The layers created during the printing process can be just 0.02 mm thick, providing a level of detail that rivals traditional machining processes.

Fast Production Times

Powder bed 3d printer can quickly produce objects by layering thin slices at high speeds instead of milling or casting components like in traditional manufacturing methods. This dramatically reduces production times from hours or days to mere minutes – allowing large batches of parts to be completed much more quickly than ever before.

Cost Efficiency

By utilizing Over Moulding 3D printing technology, companies can get higher quality components with improved tolerances, better surface finish and superior strength compared to traditional methods.

Material Diversity

Powder Bed Fusion 3D printers are capable of creating objects with a wide range of materials – ranging from plastics and metals like titanium alloys to ceramic composites and even waxes and foams! The wide palette of materials available makes this perfect for applications where multiple properties may need to be balanced, such as strength and flexibility or weight and thermal conductivity in the same item or series of items across different products lines or design iterations over time.

Increased Design Freedom

Thanks to its high resolution capabilities and ability to use multiple materials in one product, you can have greater freedom when it comes to getting innovative designs without worrying about limitations imposed by traditional manufacturing processes like milling or casting metal components requiring considerable post processing steps after manufacture.